OMT S.r.l established back to 1969. After a short time became the absolute protagonist of international market for the processing of aggregates. OMT crushers and mills have always been known for their high performance, high durability and extra ordinary power. OMT through years became indispensable tools for quarries and construction sites.

Group TEXNOKAT work exclusively with OMT crushers and mills more than 25 years. 25 years till know we offer to the market quarry units able to withstand very long work cycles without interruptions and with minimal maintenance cost.

Our long-term experience at the field of aggregate processing, admit that companies that have the ability to obtain OMT crushers and mills will never regret.

PRODUCT RANGE

FP PRIMARY JAW CRUSHER

FP PRIMARY JAW CRUSHER

FP is single toggle primary jaw crusher, suitable for crushing hard and compact materials of large sizes. The length of the jaws, their different type depending on the use requested, the shape of the crushing chamber, the size of the oscillating bearings for the most severe working conditions, the camshaft of hardened and tempered steel and the considerable moment of inertia produced by the flywheels, guarantee a high and constant production of fine quality material at low energy costs. The toggle acts as a safety element in the event of the entry of bodies that cannot be crushed; its contact surfaces roll in their seats and require no lubrication. A hydraulically assisted system, supplied as standard, allows adjustment of the outlet opening and therefore of the size of the crushed product, and also compensates wear of the jaw.

PRIMARY FG JAW CRUSHER

PRIMARY FG JAW CRUSHER

FG is granulator with reversible jaws, smooth or toothed, and a heavy-duty removable frame, suitable for crushing even compact materials. The size of the flywheels allows a considerable moment of inertia to be obtained, which facilitates the crushing process and reduces energy consumption. The shape of the jaws, their length and the configuration of the crushing chamber allows the production of less flaky material than that obtained with other similar machines. The jaw adjustment is assisted by a hydraulic cylinder, which considerably reduces intervention times and controls for maintenance. The version with a wide feed mouth is suitable to be used for primary crushing immediately before secondary or tertiary hammer mills.

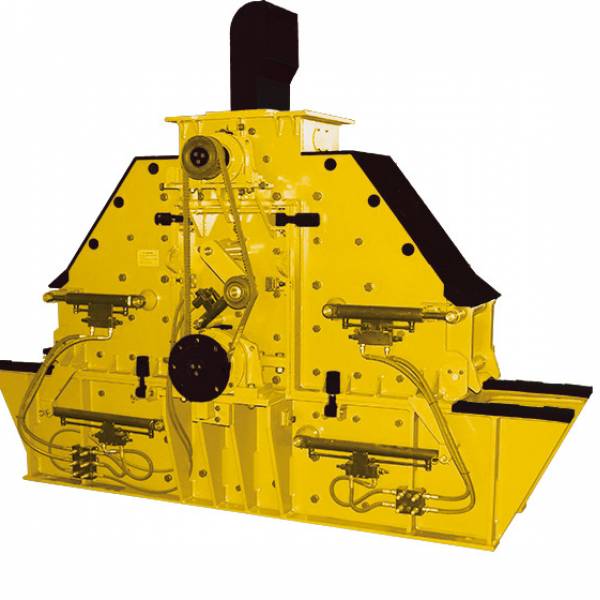

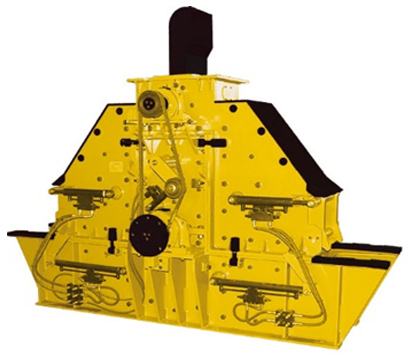

MP PRIMARY IMPACT CRUSHER

MP PRIMARY IMPACT CRUSHER

MP is primary impact crusher, particularly indicated when it is desired to obtain percentages of fine grades - with an acceptable polyhedral shape - higher than those that can be obtained with jaw crushers. Thanks to the high reduction ratio, the end product is ready to be further reduced by a tertiary mill, thus abbreviating the system crushing cycle. The adjustable armour holder allows the product dimension to be varied, within certain limits, and compensates wear of the hammers and the armour, maintaining constant granulometry of the crushed material over time. Thanks to the compression and cutting action exerted, the stake allows a finer, calibrated and more polyhedral product to be obtained, and prevents the material building up in the machine, facilitating crushing.

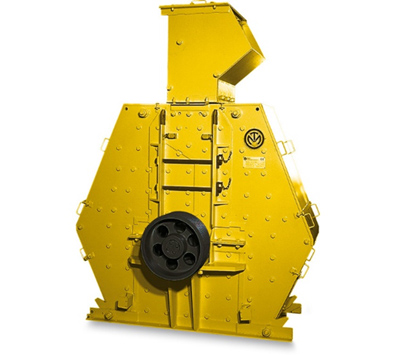

MS SECONDARY IMPACT CRUSHER

MS SECONDARY IMPACT CRUSHER

MS is secondary impact granulator, ideal for large productions after a jaw or impact crusher, but also suitable for primary crushing of material that is not too hard, with sufficiently reduced dimensions. They allow great production with a high reduction ratio in an open work cycle. If the material is not very abrasive a high reduction ratio can be obtained – from 250-300 mm to 25 mm, with recycling – and a large quantity of fine grades with an acceptable polyhedral shape. The parts of the machine subject to wear are made of manganese, but they can also be quipped with hammers and armour in special chrome alloy for crushing particularly hard and abrasive materials (basalt, diabase, granite rocks and similar). Thanks to the wide range of the rotor working speed, to the special conformation of the crushing chamber and to the possibility of adjusting the lower part of the armour holder (with a standard mechanical system or a hydraulic system on request), products with a specific polyhedral shape can be obtained for roadbed and railway ballast. The frame opens easily with a standard hydraulic system, for easy maintenance.

MIS SECONDARY HAMMER MILLS

MIS SECONDARY HAMMER MILLS

MIS is secondary mill with fixed hammers, particularly suitable for producing high percentages of fine grades with a polyhedral shape, thanks to the high reduction ratio. They can be supplied with manganese hammers and coating, or in alloy, more suitable for crushing abrasive materials. The number of armour plates installed in the crushing chamber and their geometrical profile allow the production of sand and granulates with a polyhedral shape far superior to all other hammer machines of the same type. The rotor can be fitted with 2 or 4 rows of active hammers to obtain a prevalence of sandy or granular material. The high moment of inertia that can be obtained thanks to its sturdy construction reduces specific energy consumption. Working in two directions of rotation, it also allows optimized consumption of the parts subject to wear and maintains a constant granulometric curve of the crushed product. The crushing chamber has a variable profile with standard mechanical adjustment, or hydraulic adjustment on request. The easy opening of the frame, with a standard hydraulic system, allows easy access to the inside of the machine for maintenance.

MFI TERTIARY HAMMER MILL

MFI TERTIARY HAMMER MILL

MFI is tertiary mill with fixed hammers, excellent for high productions of sand rich in fine grades with a polyhedral shape, suitable for use in concrete and bituminous mixes and in pre-mixed products. With a specific set-up of the rotor and the use of hammers with a particular geometric profile, it is possible to use these machines also for quaternary crushing. The large rotor diameter allows high peripheral speeds to be obtained with a relatively low number of revolutions, considerably reducing consumption of the parts subject to wear. The rotor, which works in two directions of rotation, can be equipped with manganese or special alloy hammers depending on the material that is to be crushed, and its conformation varies according to the product that is to be obtained. In version P it can have 2, 3 or 4 rows of hammers. The crushing chamber has a variable profile with standard mechanical adjustment, or hydraulic adjustment on request. Hydraulic opening of the machine is a standard feature.

ROCKY TRANSFORMER TERTIARY HAMMER MILL

ROCKY TRANSFORMER TERTIARY HAMMER MILL

The Rocky reversible tertiary hammer mill has been designed to transform all grain sizes considered in aggregate production to be of little interest into a commercially useable product. The Rocky hammer mill may be fed with 0-30 mm grain sizes. The Rocky mill guarantees, more than all the other mills, the performance of maintenance operations in complete safety. The innovative and exclusive multi-step casing opening system, using a carefully designed hydraulic system, allow easy access to all the parts requiring technical intervention.

CF TERTIARY CENTRIFUGAL MILL

CF TERTIARY CENTRIFUGAL MILL

CF is a centrifugal mill with a vertical axis, suitable for tertiary or quaternary crushing of even highly abrasive inert materials. The high-speed auto-crushing process that develops in these machines allows the requalifying of inert material with a rather flaky shape, improving its polyhedral shape and increasing its mechanical resistance. The particular configuration of the feeding and crushing chamber creates an air turbulence which optimises the work performance and, by separating the material from the dust, facilitates dust removal downstream. The crushing chamber is subject to limited wear, since the impeller is coated with the same material deposited in the machine. The impellers have different dimensions, depending on the final product required. Thanks to the reduced replacement of parts subject to wear and to centralized lubrication, maintenance is very simple and machine down times are very short.