The ‘little giant’ with the easy aggregate loading and the exceptional reliability in concrete production.

Except all the parameters that show the character of a plant which is manufactured by Group TEXNOKAT, PTOLEMEOS has some extra features that make him unique.

Aggregate loading can be from 0 level with loader without ramp. It does not require loading ramp due to its small size. It can be feed by any type of loader and even with a bobcat without ramp.

The operator cabin is fixed with aggregate hopper, so the machine is prewired and pre-connected. The control cabin includes: High voltage Electrical Board, Software BetonMind by Iliatoras, Air-condition, set of all the electrical and coaxial cables which is already attached to the board.

PTOLEMEOS gives the production capacity that promise in any circumstance. It is transported in only (2) normal truck and can be transported, with minimum cost, by land, sea and air. It can be set up in full operation in just (96) hours.

It operates independently even at the far distant place covering the needs of every concreting work, with the proper additions, such as: truck mounted cement silo, metallic ramp, electric generator and water tank.

It is environmentally friendly with low dust and noise emissions with low energy consumption.

|

TECHNICAL SPECIFICATION |

PTOLEMEOS 20 |

PTOLEMEOS 40 |

PTOLEMEOS 60 |

|

PRODUCTION CAPACITY |

20m3 vibrated concrete |

40m3 vibrated concrete |

60m3 vibrated concrete |

|

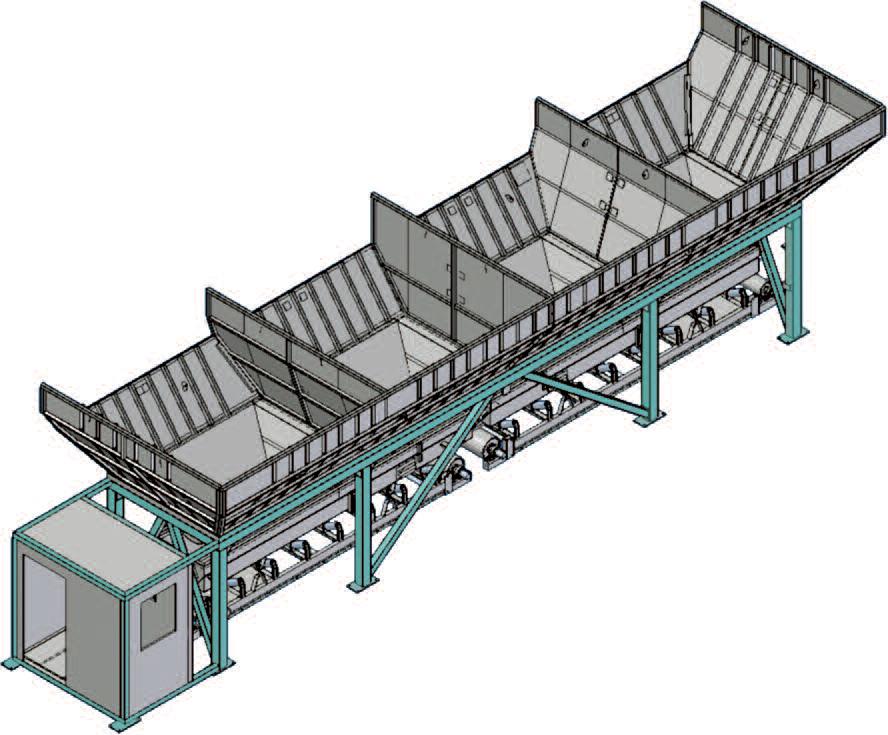

AGGREGATE STORAGE BINS |

2 compartments x 12,5m3 = 25m3 |

3 compartments x 12,5m3 = 37,50m3 |

4 compartments x 12,5m3 = 50m3 |

|

AGGREGATE WEIGHING SCALE (BELT) |

400 x 5.150mm |

500 x 7.800mm |

2 x 650 x 4.650mm |

|

MAIN CONVEYOR BELT |

400 x 14.000mm |

500 x 15.000mm |

650 x 17.000mm |

|

TWIN SHAFT MIXER |

0,5m3 SICOMA MAO 750/500 |

1m3 SICOMA MAO 1500/1000 |

1,5m3 SICOMA 2250/1500 |

|

CEMENT WEIGHING SCALE |

300 lit – with 3 load cells |

500 lit – with 3 load cells |

750 lit – with 3 load cells |

|

CEMENT SCREW CONVEYOR |

1 x Φ 168 x 9.000mm |

1 x Φ 193 x 9.000mm |

2 x Φ 219 x 9.000mm |

|

CEMENT WEIGHING SCALE FILTER |

FILTER WAM HOPPER - JET |

FILTER WAM HOPPER - TOP |

FILTER WAM HOPPER - TOP |

|

WATER WEIGHING SCALE |

200 lit – with 3 load cells |

300 lit – with 3 load cells |

500 lit – with 3 load cells |

|

ADDITIVE WEIGHING SCALE |

1 x 10 lit with 1 load cell |

1 x 15 lit with 1 load cell |

1 x 20 lit with 1 load cell |

|

WATER PUMP |

200Lit/min |

350Lit/min |

500Lit/min |

|

AIR COMPRESSOR |

3Kw, 280Lit |

3Kw, 280Lit |

3Kw, 280Lit |

|

CONTROL CABIN |

2 x 1,9 x 2,10 m |

2 x 1,9 x 2,10 m |

2 x 1,9 x 2,10 m |

|

AIR CONDITION |

9.000 BTU |

9.000 BTU |

9.000 BTU |

|

ELECTRICAL PANEL |

IP 54 |

IP 54 |

IP 54 |

|

AUTOMATION BETONMIND.NET V2.2 |

Controller with PC, 22’ screen & laser printer |

Controller with PC, 22’ screen & laser printer |

Controller with PC, 22’ screen & laser printer |

|

MANUAL FOR USE AND MAINTENANCE |

Hardcopy and USB |

Hardcopy and USB |

Hardcopy and USB |

|

TOTAL INSTALLED POWER |

60 KW |

76 KW |

97 KW |

OPTIONAL EQUIPMENT PTOLEMEOS

- 5TH / 6TH Aggregate apartment

- Metal base for aggregate hopper

- Maintenance balcony for conveyor belt

- Galvanized metal cover for conveyor belt

- Additional chemical additive weighing systems

- Micro silica weighing scale with screw conveyor

- Fly ash weighing scale with screw conveyor

- Ice flake weighing scale

- Water flow meter

- Microwave humidity sensor

- Cement silo monolithic, bolted or horizontal

- 3rd / 4th cement screw conveyor

- Steel base for stationary cement silo with maintenance platform

- Filter for cement silo

- Safety valve for cement silo

- Cement silo level indicators

- Safe loading system for cement silo

- Filter for mixer

- Moisture probe for mixer

- High pressure wash out

- Water tank

- Power generator