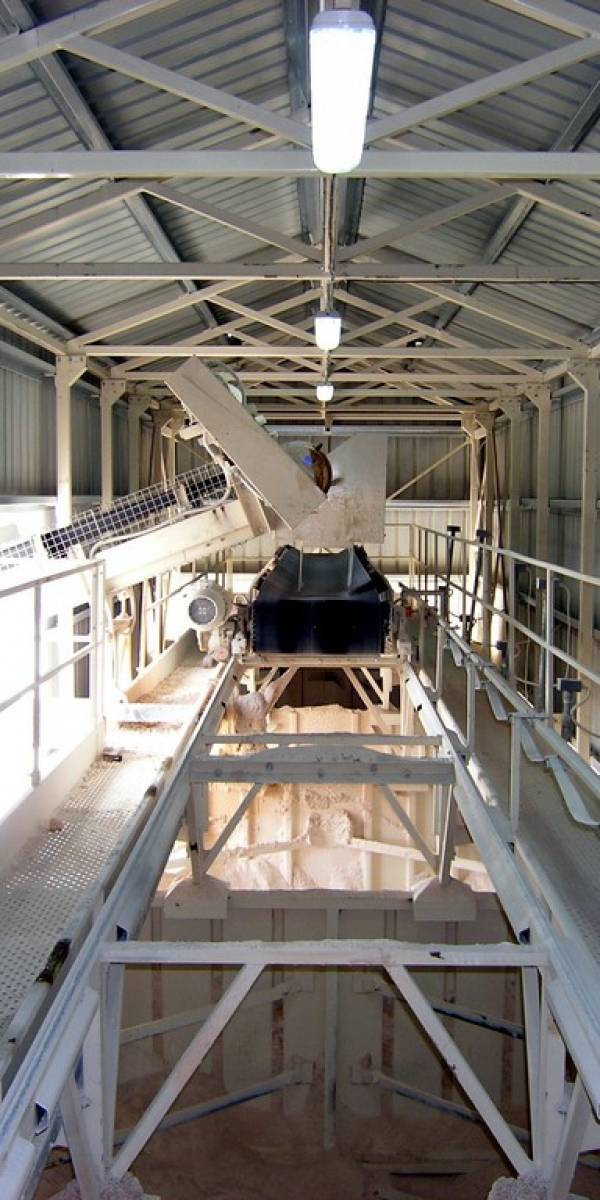

AGGREGATES PRE-LOADING SYSTEM WITH MOVABLE DISTRIBUTOR-WAGON

The total automation of concrete production can be succeeded using the aggregates pre-loading system with movable distributor-wagon which needs only one employer to operate the concrete production plant.

Using this system, your organization can contribute to the environmental protection by minimizing derricks or truck movement for the aggregates distribution into the compartments which are on a high level. In this way there is no creation of dust and noise. By this way the loading of the aggregates at earth level and the use of conveyors belts minimize truck and derricks movement and dust minimization. The pre-loading system minimizes the civil engineer work for the construction of a loading ramp.

The preloading system with the movable wagon-distributor includes:

- a) A metallic aggregate feeding hopper from 8m3 to 24m3 capacity specially designed with the appropriate inclination so the material flows without the usage of vibrators. It can also placed into the earth so the charge can be from the earth level. It includes also as optional equipment a special grid so it can handle material with big volume which are not consistent for the production of concrete and may create damage to the production.

- b) A special conveyor belt for the transportation of the aggregates material to the aggregates compartments with the appropriate inclination, belt type EP315/4/4+2 800mm wide and 28m long and safety stop wire

- c) Vertical supporting tower in the points that the technical study has shown that is needed.

- d) One (1) double direction horizontal conveyor belt for the aggregates compartments load. Rolls are placed every 60cm all over the conveyor belt on conveyor construction. The movement of the conveyor belt is upon a special metallic base that includes a non-slip service balcony. Included also are limit switches.

- e) Operating panel included in an electrical board that is placed next to the preloading hopper. Apart from the manual function, optionally we can provide an industrial remote control for the operator’s facilitation. Also, in the pre-loading system as optional equipment we may include the operation in the main automation of the plant so that it functions automatically from the operation cabin.