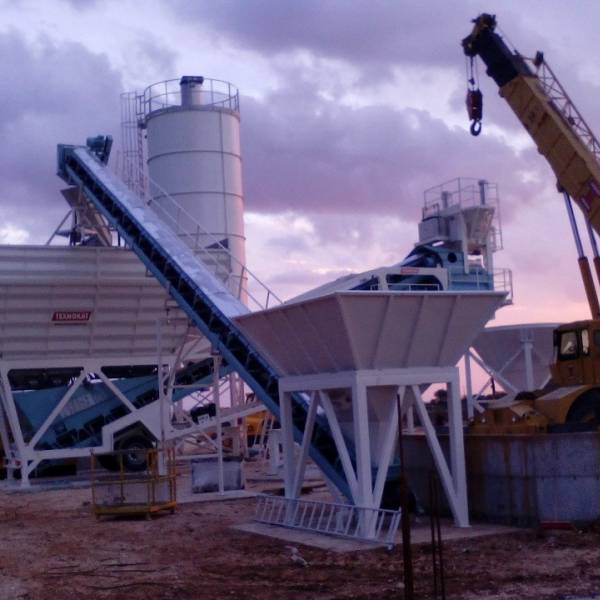

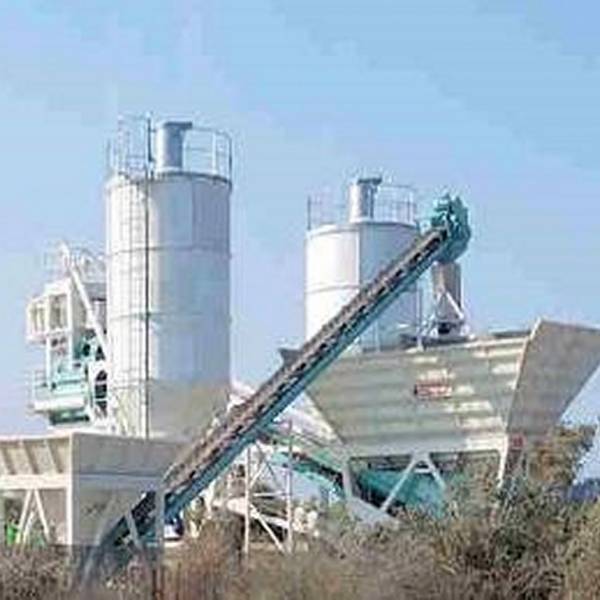

PRE-LOADING SYSTEM FOR MOBILE UNIT

The total automation of concrete production can be succeeded also at mobile units. Using the aggregates pre-loading system with vertical scoop which needs only one employer to operate the concrete production plant.

Using this system, your organization can contribute to the environmental protection by minimizing derricks or truck movement for the aggregates distribution into the compartments which are on a high level. In this way there is no creation of dust and noise. By this way, the loading of the aggregates at earth level and the use of conveyors belts minimize truck and derricks movement and dust minimization. The pre-loading system minimizes the civil engineer work for the construction of a loading ramp.

The preloading system with the vertical scoop includes:

An intel 4 m3 aggregate supply metal hopper, special designed and decreed in order to maximize raw materials smooth flow and minimize time of supplying without vibrating usage

A special designed aggregate storage conveyor belt. Special futures of that belt are a safety rope and a safety grid for the operator’s security.

One (1) rotating scoop for the delegate supply of every chamber of aggregate storage unit.

The system includes guidance for the operation, with an electrical panel placed next to the inlet hopper. Optionally we can provide an industrial remote control 100m range for the operator’s facilitation.