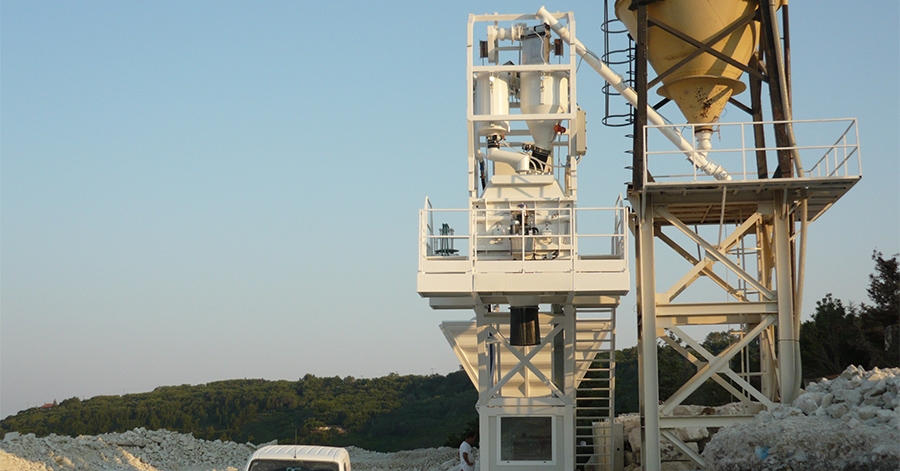

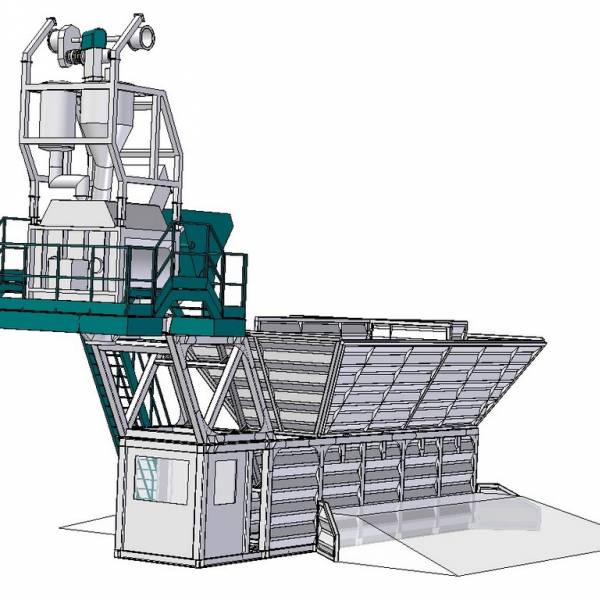

The flying batching plant fully ready for action in record time (6 hours). The result of new cognizant thinking is the leading, reliable, complete and containerized batching plant HERMES 40.

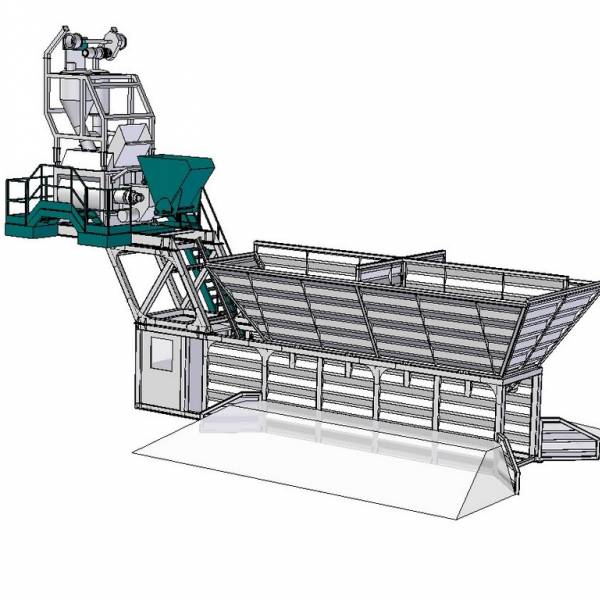

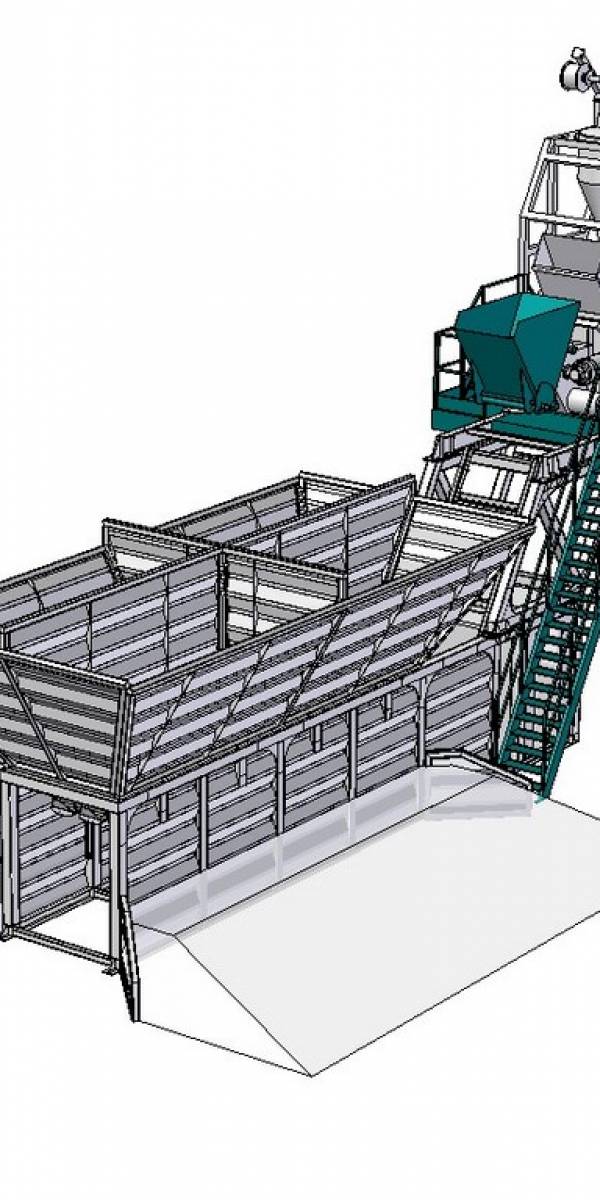

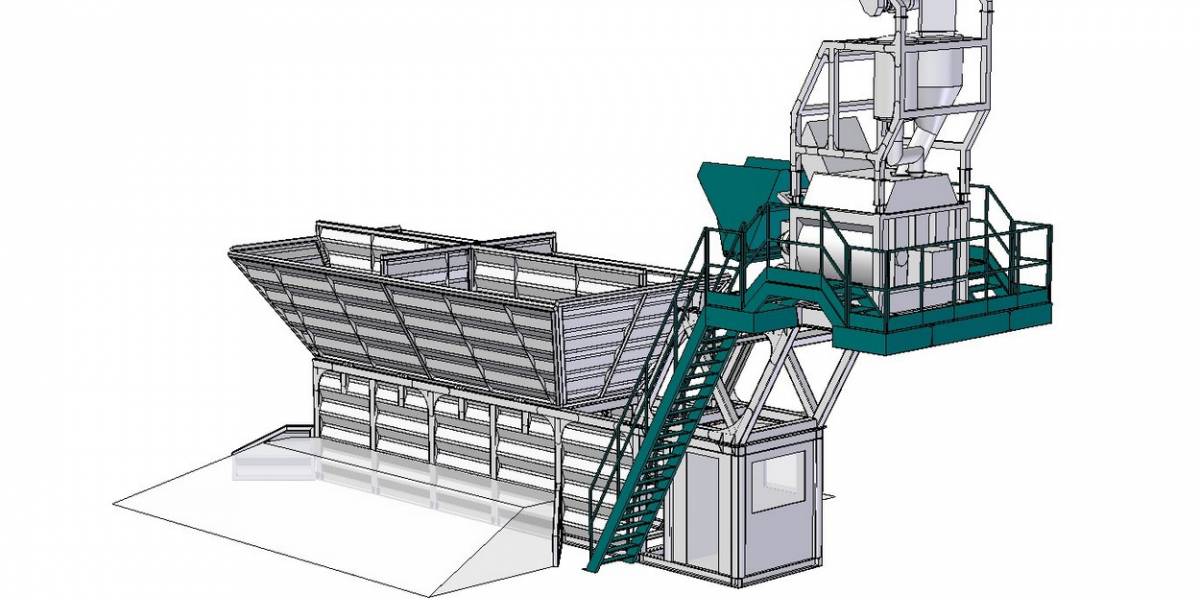

The entire production of the new line of “HERMES 40” based on easy erection and disassembly and indeed very easy and economical to be transferred because the unit is manufactured in the form of two “Open” containers 40’.

As the entire construction of this particular unit is self-wired and cascaded circuit, for which it does not require any particular individual or any further work to be done while installation.

The area which is required for the installation of the batching plant is very minimal (20m X 20m) which compile less expense for the required infrastructure.

The Containerized Mobile Concrete Batching Plant HERMES 40, has been primarily fully developed by Group TEXNOKAT and is patented based on the ΟΒΙ 2012/1007525 certificate.

The “HERMES” comes with all the required equipment, wires, the piping on the platform seating and their transfer as well as the metallic wall support. By adding optional components such as mobile silo cement, electric generator and water tank can work independently and in the most distant point by addressing the needs of each project of batching process.

|

TECHNICAL SPECIFICATION |

HERMES 40 |

|

PRODUCTION CAPACITY |

40m3 vibrated concrete |

|

AGGREGATE STORAGE BINS |

4 compartments x 15m3 = 60m3 |

|

AGGREGATE WEIGHING SCALE (SKIP) |

1,500 m3 |

|

SKIP HOIST |

1,500 m3 |

|

MIXER |

TWIN SHAFT 1m3 SICOMA MAO 1500/1000 |

|

CEMENT WEIGHING SCALE |

600 lit – with 3 load cells |

|

CEMENT SCREW CONVEYOR |

1 x Φ 193 x 9.000mm |

|

CEMENT WEIGHING SCALE FILTER |

FILTER WAM HOPPER - JET |

|

WATER WEIGHING SCALE |

300 lit – with 3 load cells |

|

ADDITIVE WEIGHING SCALE |

1 x 20 lit with 1 load cell |

|

WATER PUMP |

700Lit/min |

|

AIR COMPRESSOR |

4Kw, 500Lit |

|

CONTROL CABIN |

2 x 1,9 x 2,10 m |

|

AIR CONDITION |

9.000 BTU |

|

ELECTRICAL PANEL |

IP 54 |

|

AUTOMATION BETONMIND.NET V2.2 |

Controller with PC, 22’ screen & laser printer |

|

MANUAL FOR USE AND MAINTENANCE |

Hardcopy and USB |

|

TOTAL INSTALLED POWER |

70 KW |

OPTIONAL EQUIPMENT HERMES 40

- Additional chemical additive weighing systems

- Micro silica weighing scale with screw conveyor

- Fly ash weighing scale with screw conveyor

- Ice flake weighing scale

- Water flow meter

- Microwave humidity sensor

- Moisture probe for mixer

- Cement silo monolithic, bolted or mobile

- 2nd / 3rd cement screw conveyor

- Steel base for stationary cement silo with maintenance platform

- Filter for cement silo

- Safety valve for cement silo

- Cement silo level indicators

- Safe loading system for cement silo

- Aggregate pre-loading system with remote control (vertical scoop)

- Filter for mixer

- High pressure wash out

- Water tank

- Power generator