CONCRETE RECYCLING

WAMGROUP is the global market leader in Screw Conveyors and holds top-ranking positions in each of its product lines in the field of Bulk Solids Handling & Processing.

The long-standing cooperation of Group TEXNOKAT with the leading Italian company WAM provides to our customers with the ideal solutions for the recycling of ready-made concrete while protecting the environment. We offer advanced technical solutions in Aggregate Reclaiming for concrete batching plants focused on economy, efficiency and wear resistance.

DESCRIPTION

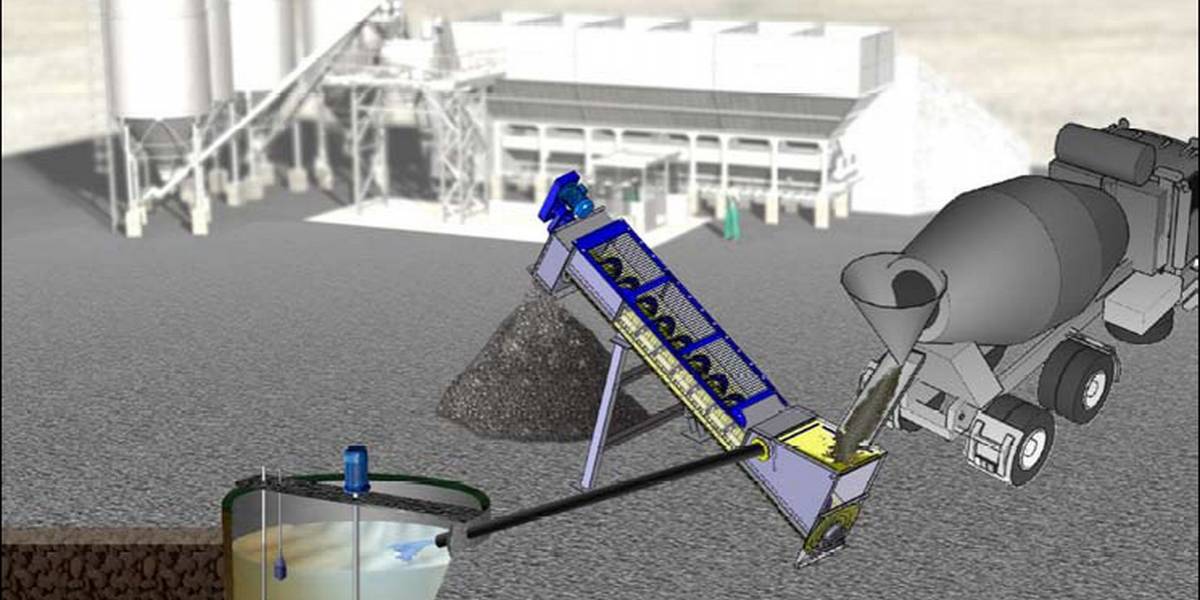

The CONSEP 5000 is an innovative Aggregate Reclaimer used in ready-mixed concrete batching plants for reclaiming concrete washed out from truck mixers, as well as in pre-cast concrete batching plants for the recovery of concrete from the moulds.

The CONSEP 5000 is manufactured from galvanized carbon steel. It is made up of a U-shape trough and a large inlet batch hopper, both lined with wear-resistant SINT engineering polymer. The CONSEP 5000 comes with a wide outlet spout, a ribbon screw with individually replaceable segments coated with wear-resistant SINT engineering polymer, a bolted trough cover grid, and a robust gear motor which suits the application.

FUNCTION

The CONSEP 5000 Aggregate Reclaimer allows recovery of residual concrete and wash water from truck mixers or concrete pumps enabling concrete manufacturers to comply with eco-standards with special reference to the environmental impact, prevention of contamination and recirculation of waste water and aggregates in concrete plants.

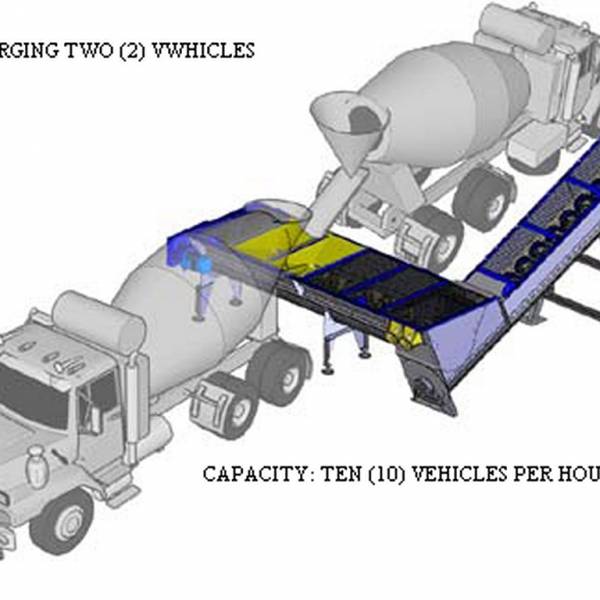

The different CONSEP 5000 configurations enable unloading of up to 4 vehicles at a time with a recycling capacity of up to 20 m3/h. Excellent solids-liquid separation and washing of aggregates, as well as large-capacity settling and extracting of fines, with a particle size of down to 0.2 mm, position CONSEP 5000 as a top performing machine in this sector.

FEATURES

- Flow rate: 20 m3/h (12 cfm) of diluted concrete

- Drive power: 5.5 kW (7.5 HP) 220-240/380-420 V, 50 Hz; 440-480 V, 60 Hz

- All fabricated parts manufactured from galvanized carbon steel

- Heavy-duty ribbon flight screw in high-resistance steel painted and coated with wear-proof, non-stick SINT engineering polymer

- Trough and batch hopper lined with wear-proof, non-stick SINT engineering polymer

- Sturdy, extra-heavy-duty design

- Internal, replaceable maintenance-free lower bearing

BENEFITS

- Quick Return On Investment

- Excellent solids-liquid separation and washing of aggregates

- Reduction of maintenance costs for the End User (SINT non-stick properties and resistance to abrasion, modular components)

- Low running costs (low water and energy consumption)